|

All Kothari Print Pro editions share the same technology platform. Based on the end-use requirements each of these edition offer different features relevant to the application.

|

Introduction.

This edition of Kothari Print Pro is a handy companion to any one involved in the screen making/ prepress film production for photo masking. Starting with grayscale separations to printing the halftone screens is all very simple with this tool. Various screening options including second order stochastic screens for moiré free printing and marking options are available.

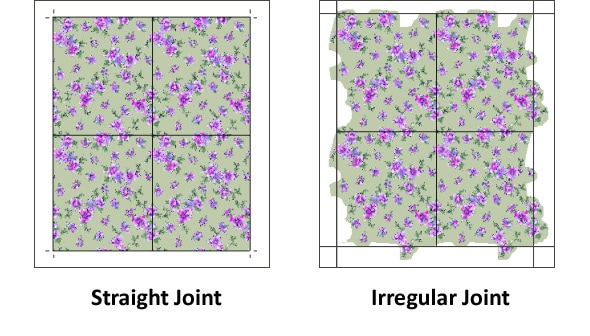

Kothari Print Pro provides powerful options traditionally possible only with high end postscript printers and RIPS. It gets closer to designer by understanding the channel based design formats directly like Photoshop PSD file format in addition to separations in Tiff, EPS, DCS 2.0, PS, and PDF. The software can be used for both offset and screen printing. It offers high quality screening with step and repeat and irregular dubbing at the joints.

Print Pro also offers custom printer drivers for various large format printers and a few CTS machines. These drivers offer full control over the machine options from the software using its interface.

This tool finds use in screen making/ prepress film production for the printing process in industries, like Textile printing, Garment printing, Offset printing, Gravure printing, Service bureaus, ceramic printing, wall paper industry, PCB manufacturing etc.

Kothari Print Pro provides powerful options traditionally possible only with high end postscript printers and RIPS. It gets closer to designer by understanding the channel based design formats directly like Photoshop PSD file format in addition to separations in Tiff, EPS, DCS 2.0, PS, and PDF. The software can be used for both offset and screen printing. It offers high quality screening with step and repeat and irregular dubbing at the joints.

Print Pro also offers custom printer drivers for various large format printers and a few CTS machines. These drivers offer full control over the machine options from the software using its interface.

This tool finds use in screen making/ prepress film production for the printing process in industries, like Textile printing, Garment printing, Offset printing, Gravure printing, Service bureaus, ceramic printing, wall paper industry, PCB manufacturing etc.

Highlights.

- Print Images at virtually unlimited resolution and size (subject only to the limitation of the resolution of the printing device).

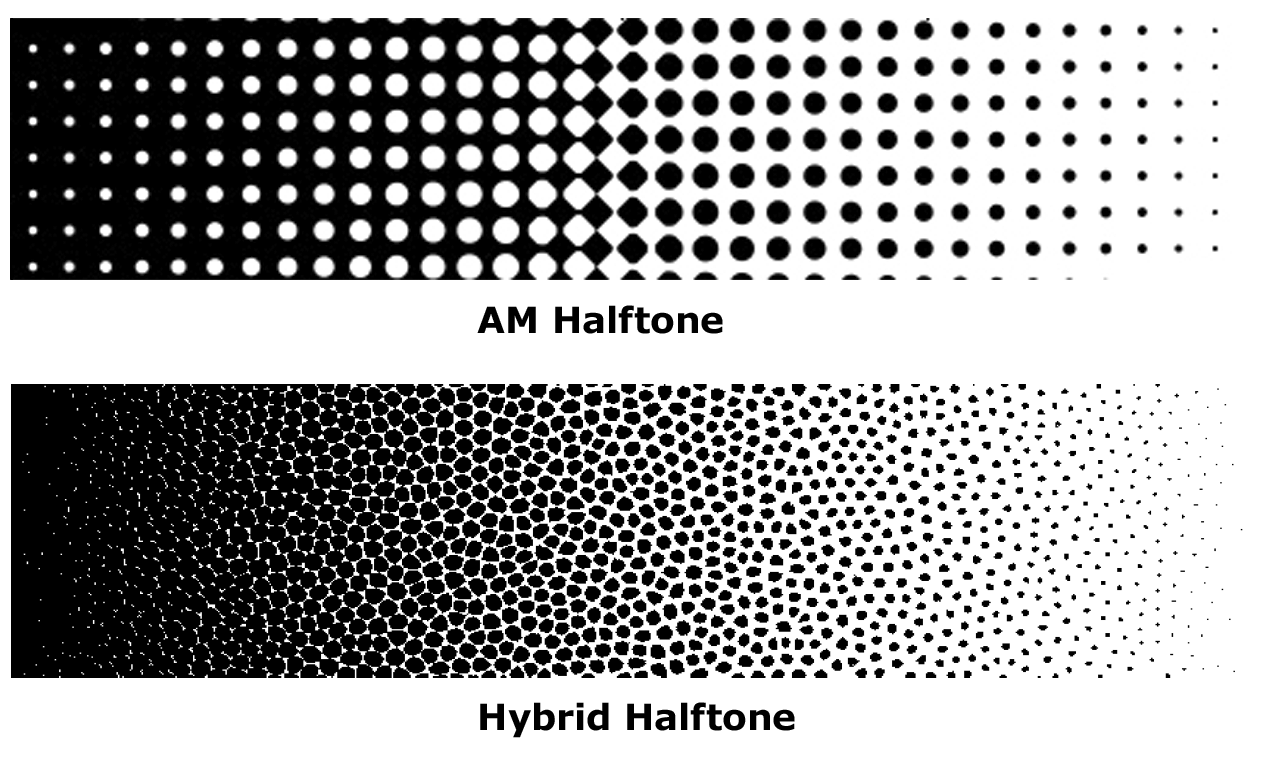

- Supports both AM and Second order Stochastic (hybrid) screens.

- LPI and angle of halftone screens is also not a limitation (in practice limited only by the resolution of the printing device).

- 4096 gray levels for AM halftone screens to support more details in the images.

- 34 different AM halftone shapes available in user defined LPI and angle.

- Nesting - a powerful feature for saving expensive media by placing multiple jobs on the same page. Different screening options can be applied to each Job on the page.

- Emulsion down and Film inversion support.

- For large format textile printing, it reduces the time and labor in step and repeat and joint dubbing.

- Seamless halftoning at repeat joints.

- Special Honeycomb AM dots for rotary screens (A technology for textile printing).

- Handles large images with ease by the help of its Memory Management system that uses Hard Disk as scratch space.

- Bi-cubic interpolation for high quality output.

- This software can also interface with any printer offering MS Windows compatible windows driver. In such case, however the limitations on output imposed by the Windows printer driver shall apply.

Please see our Technology page to learn more about these features.

All the features presented here are available in full featured version of the CTS edition of Kothari Print Pro software. Kindly note that available features in your version of the software will depend upon the configuration purchased by you. OEM versions of our software can differ significantly from full featured version of the software and that too can vary from OEM to OEM.

Technical Specification.

- Requires a PC based on Intel core i3 running at 2.3 GHz or better processor. RAM 3GB or more.

- Operating system: Microsoft windows 7 or later.

- Hard Disk: Hard drive requirement varies based on your usage requirement. We recommend 500 GB or more fast SATA/ SSD (SSD preferred), with atleast 50GB of free space.

- Monitor: 24 bit color or better, with minimum resolution of 1366x768 pixels (recommended 1920x1080 pixels).

- One USB port for software dongle.