Charu Reactive Inks.

Focus on Quality.

In order to achieve high quality consistently, besides ink formulations, we process dyestuff ourselves to make it ready for inkjet purposes. All the processes whether it is dye purification or particle size reduction and stabilization by nano-grinding, we do it all in-house. This provides us with great degree of control over the quality we produce and allow us to set our bars higher for it.

In-house processing of dyestuff also allows us to respond to customer needs and demand more swiftly as we are no longer limited by what is available in the market, which is typically the case with exclusive formulation companies.

In-house processing of dyestuff also allows us to respond to customer needs and demand more swiftly as we are no longer limited by what is available in the market, which is typically the case with exclusive formulation companies.

All our inks are high in dye loading in order to deliver the maximum color gamut. Therefore, we don't feel the need to have separate series for high density inks.

Charu Reactive ink is part of our wet chemistry for textiles.

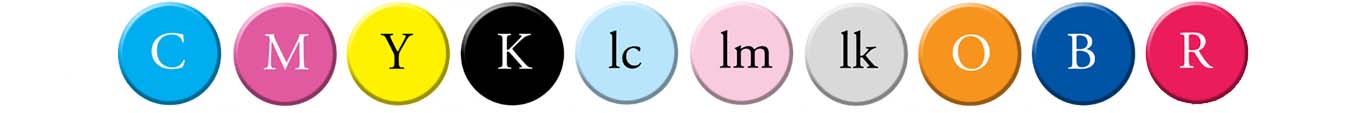

Available colors

Our Charu Reactive inks are water based inkjet inks, available in range of 10 colors to choose from namely, Cyan, Magenta, Yellow, Deep Black, Light Cyan, Light Magenta, Light Black, Orange, Blue and Red.

Ink Characterization

|

Supported Print-heads

Inks are available for all major type of aqueous print-heads available in the market - Epson Dx4, Dx5, Dx6 and Dx7, Konica Minolta 512i, 1024i, 512 and 1024, Kyocera KJ4B, Ricoh Gen4 and Gen5, Seiko 255 and 508, Spectra SG1024. These inks are tuned to individual head viscosities and surface tension properties for best performance.

Applications

Our Charu Reactive inks are suitable for printing on Cotton, Rayon, Linen, Viscose, Bamber, Silk, Wool and Nylon* fabrics.

* With suitable pre-treatment and Acid Black.

* With suitable pre-treatment and Acid Black.

Fixation method

Wet Steam with 95%+ (non condensing) RH at 102 deg C. Timing to be adjusted as per the steamer. Generally between 8 to 45 minutes based on steamer and the fabric type.

Explore our Charu Reactive inks In combination with our Kothari Print Pro to get maximum juice out of expanded gamut offered by Spot color inks. Read to know more...