|

All Kothari Print Pro editions share the same technology platform. Based on the end-use requirements each of these edition offer different features relevant to the application.

|

Introduction.

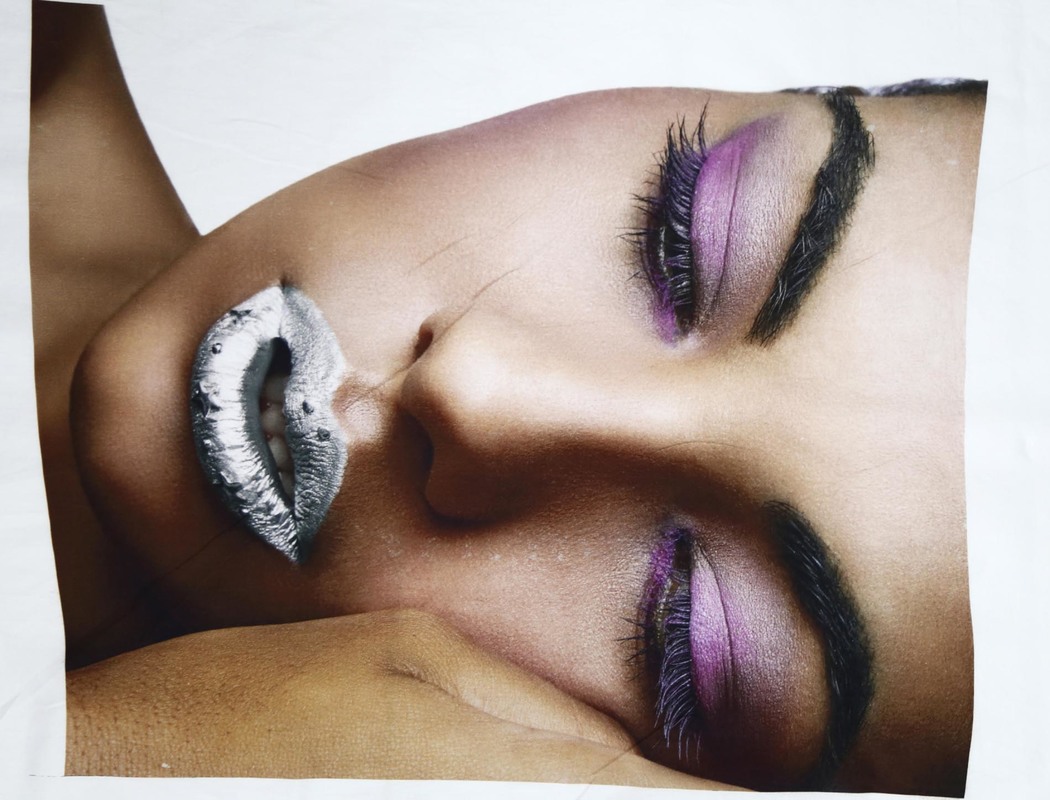

Unmatched Print quality with excellent details have been the hallmark of our Kothari Print Pro RIP and color management software for textiles.

Kothari Print Pro has been created for the most demanding workflows in today's textile printing environment. It has been created keeping in mind the specific needs of textile designers and printers.

For workflows starting from color separated files meant for conventional printing, it takes care of colorways to simulation of proofs on a digital printer. For on-demand digital print workflows, starting with a customer order from the web to print, its XML Job tickets based Job workflow takes care of all details required for print automation. RIP output can be controlled through XML job tickets.

The software's powerful memory management tools take care of handling any amount of design data in a given amount of RAM, to provide consistent and reliable performance. Being a multi-threaded application the software rips the images at blazing speeds, providing extremely fast throughput.

With its layout tools, large designs with different step and repeat settings, colorspace can be assembled very quickly. Infact, the software is capable of handling variable transparency in the images and compose them on the fly during printing, where each of the image in the layout being composed, could have a different colorspace.

Enjoy the expanded gamut of colors using its sophisticated CMM (Color management module) and its N-color profiling engine that allows profiling of printing devices with upto 12 colors including light color shades. Our patent pending module takes care of color profiling with difficult to handle fluorescent colors, providing the necessary gamut expansion. The CMM also allows profiling of devices like scanner and monitor. The Spot color tools provides you maximum control in reproduction of spot shades.

In summary, Kothari Print Pro (DTP edition) offers a collection of innovations designed to make the work of a digital textile printer simple. The software exceeds expectations in print quality on textiles with its smooth color gradations and details in shadows and highlights.

Kothari Print Pro has been created for the most demanding workflows in today's textile printing environment. It has been created keeping in mind the specific needs of textile designers and printers.

For workflows starting from color separated files meant for conventional printing, it takes care of colorways to simulation of proofs on a digital printer. For on-demand digital print workflows, starting with a customer order from the web to print, its XML Job tickets based Job workflow takes care of all details required for print automation. RIP output can be controlled through XML job tickets.

The software's powerful memory management tools take care of handling any amount of design data in a given amount of RAM, to provide consistent and reliable performance. Being a multi-threaded application the software rips the images at blazing speeds, providing extremely fast throughput.

With its layout tools, large designs with different step and repeat settings, colorspace can be assembled very quickly. Infact, the software is capable of handling variable transparency in the images and compose them on the fly during printing, where each of the image in the layout being composed, could have a different colorspace.

Enjoy the expanded gamut of colors using its sophisticated CMM (Color management module) and its N-color profiling engine that allows profiling of printing devices with upto 12 colors including light color shades. Our patent pending module takes care of color profiling with difficult to handle fluorescent colors, providing the necessary gamut expansion. The CMM also allows profiling of devices like scanner and monitor. The Spot color tools provides you maximum control in reproduction of spot shades.

In summary, Kothari Print Pro (DTP edition) offers a collection of innovations designed to make the work of a digital textile printer simple. The software exceeds expectations in print quality on textiles with its smooth color gradations and details in shadows and highlights.

We cover requirements of a textile printer like no one else.

Highlights.

- Color Control.

- Color managed workflow. Open images in any color space (RGB, CMYK, Lab) for printing. Embedded color profiles in images are read and recognized for proper interpretation of the intent of the designer.

- 16 Bit color processing pipeline.

- Color tools like Color Book, Direct Color Editing (DCE) and Direct Channel Firing (DCF) for managing Spot colors in the images.

- Color profiling tools. With easy to use wizard based interface, these tools are best in the class, allowing for ink linearization, ink restriction/ limit and color profiling. They are specially designed to work with extended primaries (spot colors), besides CMYK in a N-color ink configuration. Working in the ink space with full color gamut spawned by the inks used, the software can also use fluorescent inks as process primaries for gamut enhancement to the maximum extent. The tool provides sophisticated method to blend light and dark colors to achieve maximum smoothness in the prints without loosing the color gamut.

- Create profiles for printer with upto 12 colors.

- UCR/GCR control with CMYK and Spot color primaries.

- Support for Auto/ Manual gray balancing of printer profile.

- Generate profiles for Monitor and Scanner in addition to printers.

- Ink cost calculator. Compute the print cost for each print based on the ink consumption. This allows you to know your cost of printing before you commit for an order.

- Job tracking and accounting. Track usage of the printer with respect to the jobs printed, their print settings, number of copies and ink consumed. MIS can be generated for Job accounting purposes. Multiple printers can be tracked and programmed for automatic reporting in combination with our KoJac.

- XML based, barcode controlled workflow for Job automation. Designed to bring efficiency at the shop floor and reduce chances of errors in production, this is a must have tool no matter what your size of business is. If you are accepting orders through the web then you can automate your production process by directly generating XML tickets and placing them in the queue and tagging the fabric with corresponding barcodes. Alternatively, if you don't use the web then also, you can generate XML tickets using our Job panel for all the jobs. This panel is also capable of pulling data from a database. The RIP software takes instruction from the XML ticket and knows from there, how to process the incoming Job. Also, the moving XML Job ticket in your network allows your IT systems to keep track of the progress made on a particular Job as it moves through various stages of its life cycle - from order point to printing until shipment. As a business owner, it helps you plan your production and supervision more efficiently, reducing chances of mistakes. This frees you from production blues and let you focus on your task of managing your business!

- Image handling. Support most of the known Image file formats including native Photoshop format with Channels. The software also reads, interprets and uses transparency in the images.

- Textile Specific features.

- Generate unlimited colorways/ matchings without consuming physical memory.

- Step and Repeat.

- Proof multi-color separations for conventional textile screen printing by directly putting halftone/ raster in the Kothari Print Pro software and printing it as a simulated output with each color separation having its own halftone definition.

- Layout.

- Nesting. Allows the user to use the print area to quickly assemble multiple images and nest them for printing. These nested images could be quick strike-offs in different color space or different colorways of the same design. The nesting also results in optimizing space to save media wastage.

- Flexible image composing. In the same print area, you can place multiple images with transparent background to compose. It treats every image as a layer. Each layer can be in different color space (RGB, CMYK, Lab, multichannel etc.). Each of these layer can have different step and repeat parameters. Since textile designs are typically large, creating such original designs with such variable parameters could result in huge image files and take a lot of time, whereas doing this in Kothari Print Pro is simple and easy task that doesn't require much time or memory space.

- Output Quality.

- Bi-cubic expansion of images for excellent details and resolution enhancement.

- Advanced dithering with variable dot control for exceptional smoothness and print quality.

- Reliability and ease of use.

- Advanced Memory management for the handling almost unlimited size of image data without significant impact on performance.

- No limit on the RIP output size.

- Multi-threaded application with exceptional ripping speed.

- Stable platform that rarely crashes, allowing you to focus on your Job than worrying for the next event !

- Intuitive user interface.

- Hide print settings complexities behind the user defined definitions as print environments. These can be shared among various print stations using printer of same type and recalled easily from a drop down list.

- Installation of new print modes and taking backup of existing print modes is easy. This allows to keep backup of various customization done for printing, in due course of time.

- Handle more than one printer with the same software (subject to the limitations imposed by the processing capabilities of the PC).

- Port Manager. Define ports and associate them with the name of the Printer as identified on the shop floor for easy recall.

- Print Queue Manager. Load, RIP, Print and Manage Jobs in the same queue going to various printers. Job priorities can be changed by simply moving them up and down in the list. Store RIPPED jobs on the disk for future recall.

Please see our Technology page to learn more about these features.

Technical Specification.

- Requires a PC based on Intel core i3 running at 2.3 GHz or better processor. RAM 4GB or more.

- Operating system: Microsoft windows 7 or later.

- Hard Disk: Hard drive requirement varies based on your usage requirement. We recommend 500 GB or more fast SATA/ SSD (SSD preferred), with atleast 100GB of free space.

- Monitor: 24 bit color or better, with minimum resolution of 1366x768 pixels (recommended 1920x1080 pixels).

- One USB port for software dongle.

Gallery of Prints.

Following prints were made using Ricoh Gen5 based Ichinose 2040 printer on cotton satin fabric with CMYKLkLmOB inkset. The photos of the prints clearly illustrates the capabilities of Kothari Print Pro to bring life to images even on fabric !.